Go Back

- Your solutions

- Products

- Services

- Industries

- Contact

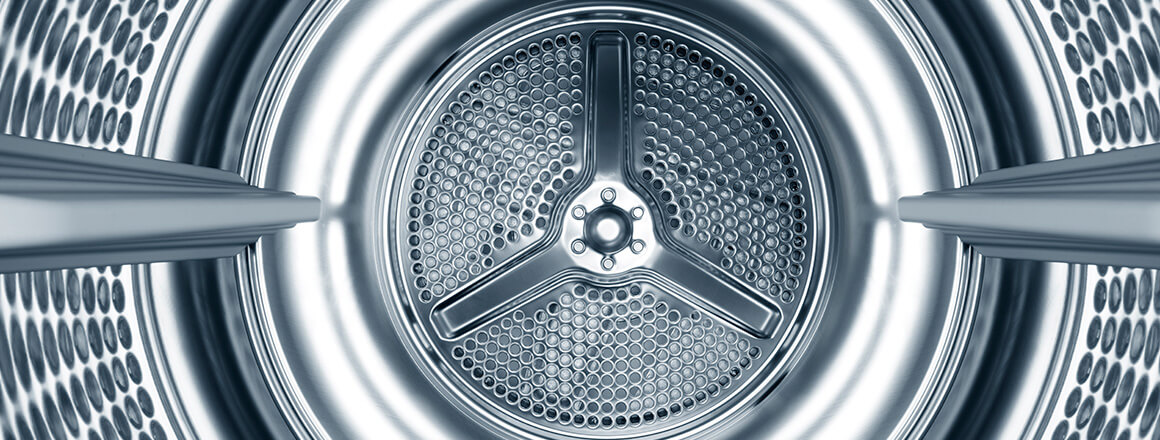

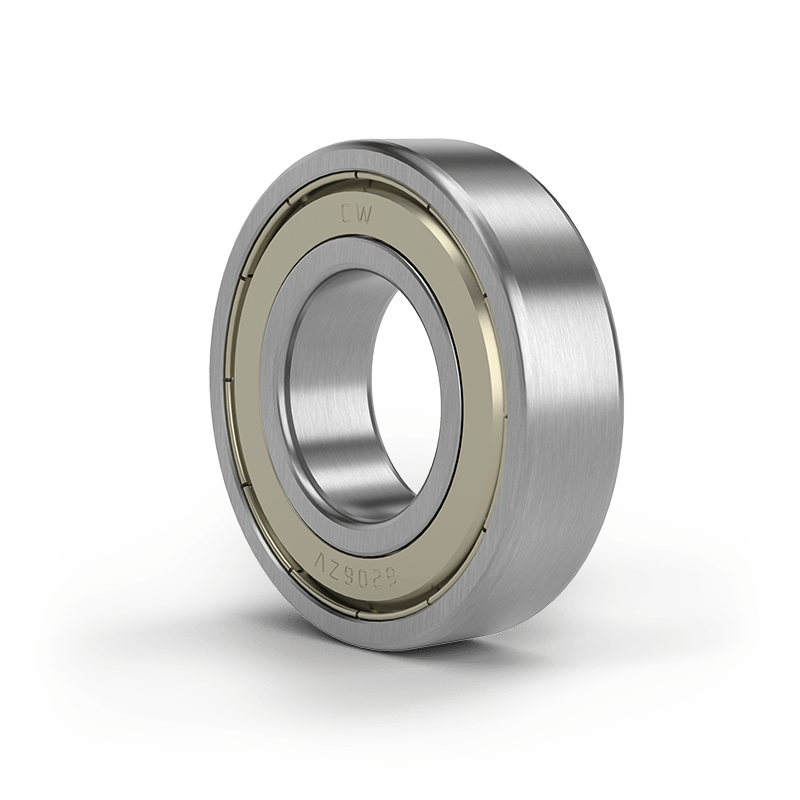

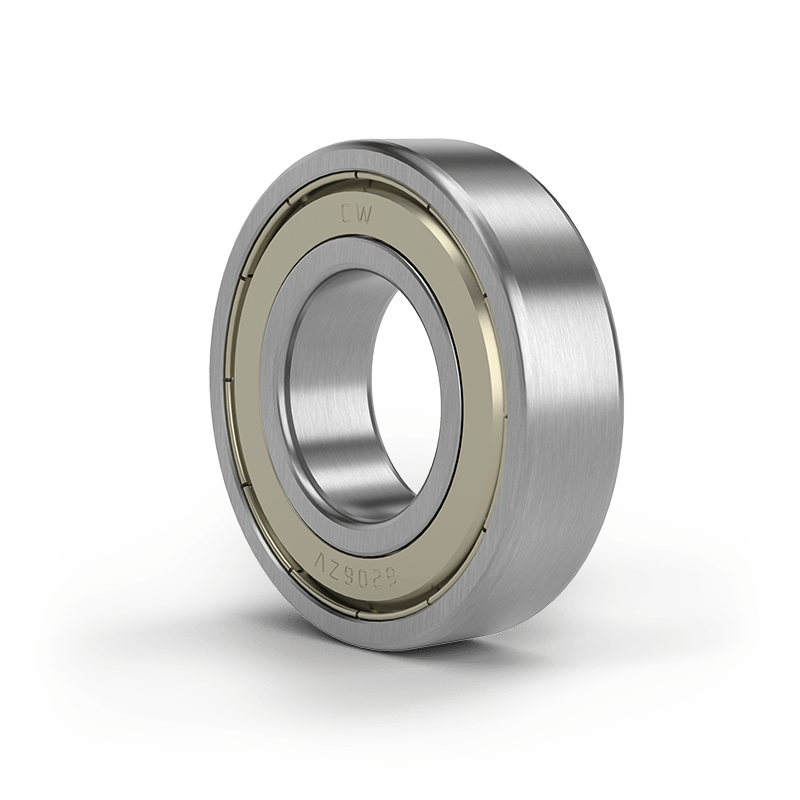

In the washing machine, the drum bearing is a particularly demanding challenge. For a high energy efficiency class, the bearings must be particularly low-friction. In addition, no loud noises should occur during the washing process. And finally, the drum must be able to move high loads at different speeds for as long as possible.

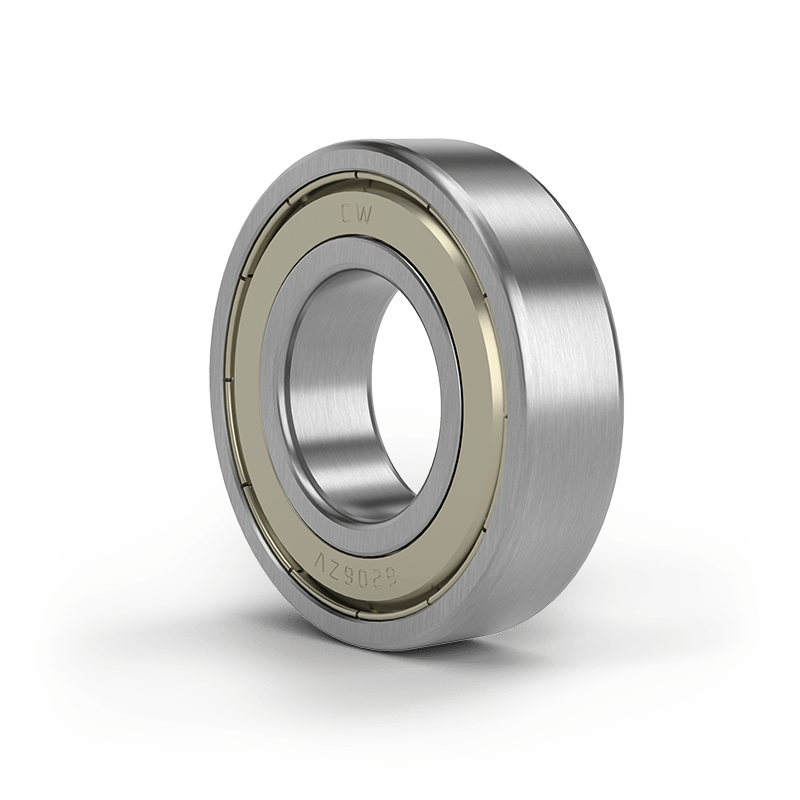

To absorb the high centrifugal forces, we use a 100Cr6 steel that has been degassed under vacuum for your ball bearings. Non-metallic inclusions are thus reduced and the service life of your application is extended.

Your requirements

The first question here is how the drum is driven: directly or via a belt. Both philosophies have their advantages and disadvantages. Certainly, the direct drive puts a little more strain on the ball bearing. In order to save installation space, the focus is increasingly on higher power density and thus on smaller ball bearings.

What remains the same are the classic requirements for the bearings in terms of operating life as well as energy efficiency and low noise. Simply ask our experienced application engineers for advice on choosing the right ball bearing.

Your requirements

With the practical ball bearing configurator from CW Bearing, you can easily put together your individual solution and receive the corresponding quotation directly on request.

Do you have specific questions about a rolling bearing in your application? Then please feel free to contact me directly.