Go Back

- Your solutions

- Products

- Services

- Industries

- Contact

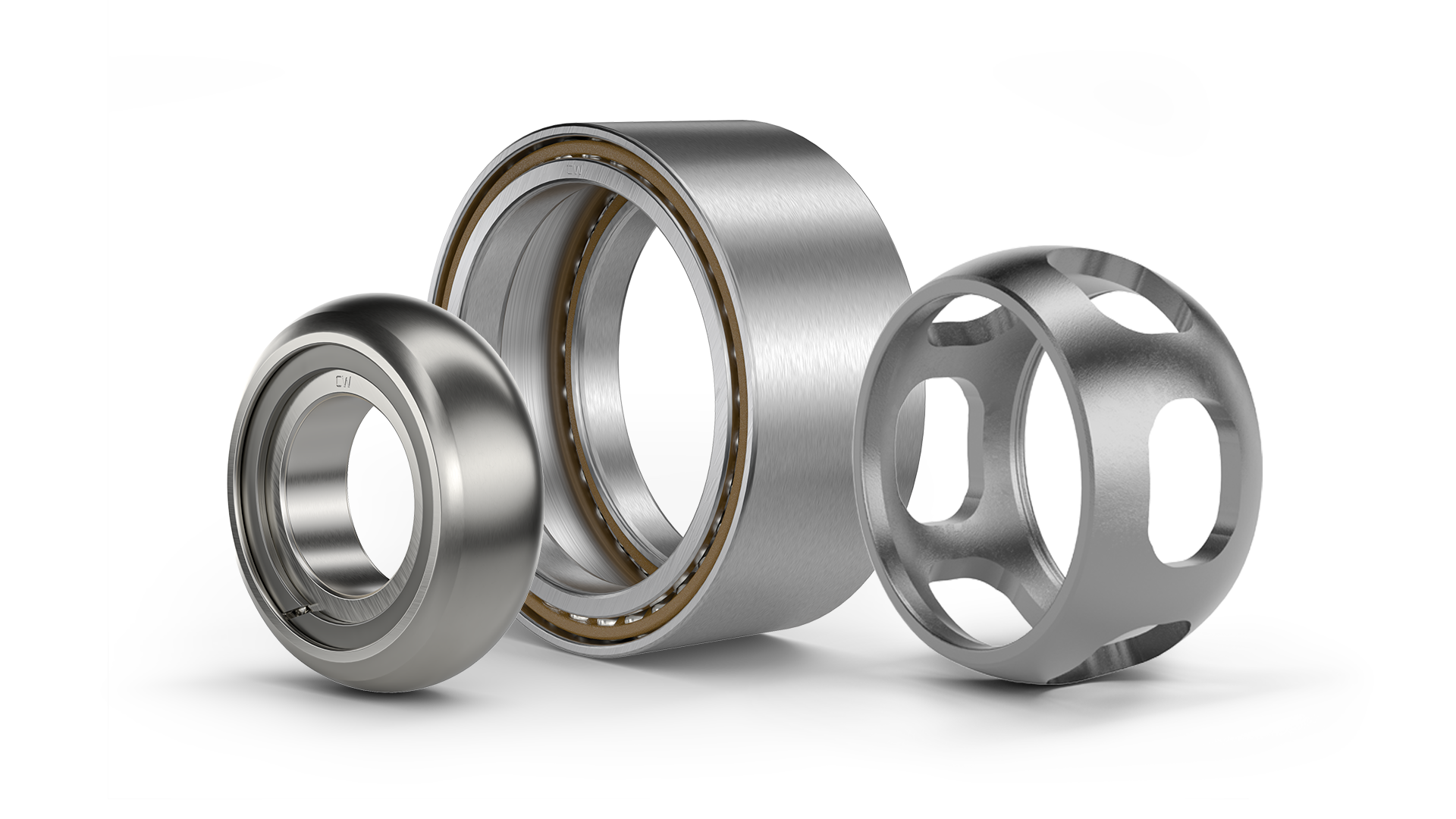

You need a completely individual solution? Then you are 100% right with us! Simply tell us your technical requirements or upload your specifications to us. We will suggest geometries, ball sizes, greases and tolerance classes to you. Our flexible production lines are ideally suited for the series production of your bearings.

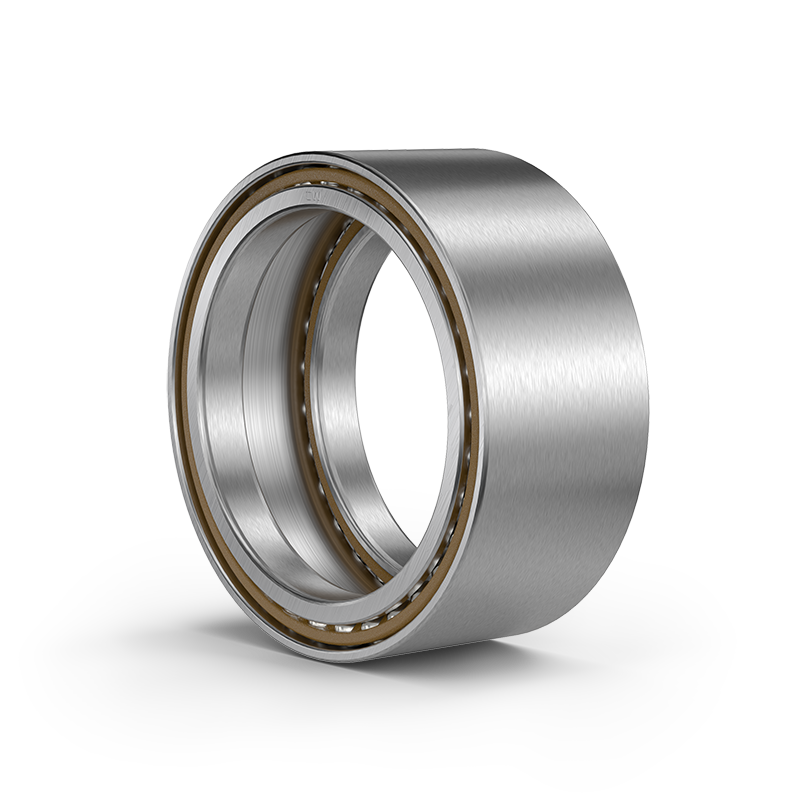

DAC bearings are used, for example, in steering gears and anti-roll bars. The size is specified. The aim is to achieve the highest possible tilting rigidity in combination with a large axial and radial load carrying capacity of the bearing.

The bearing must run reliably over the entire service life of the system. At the same time, friction and noise must not fall by the wayside. We are happy to accept this challenge.

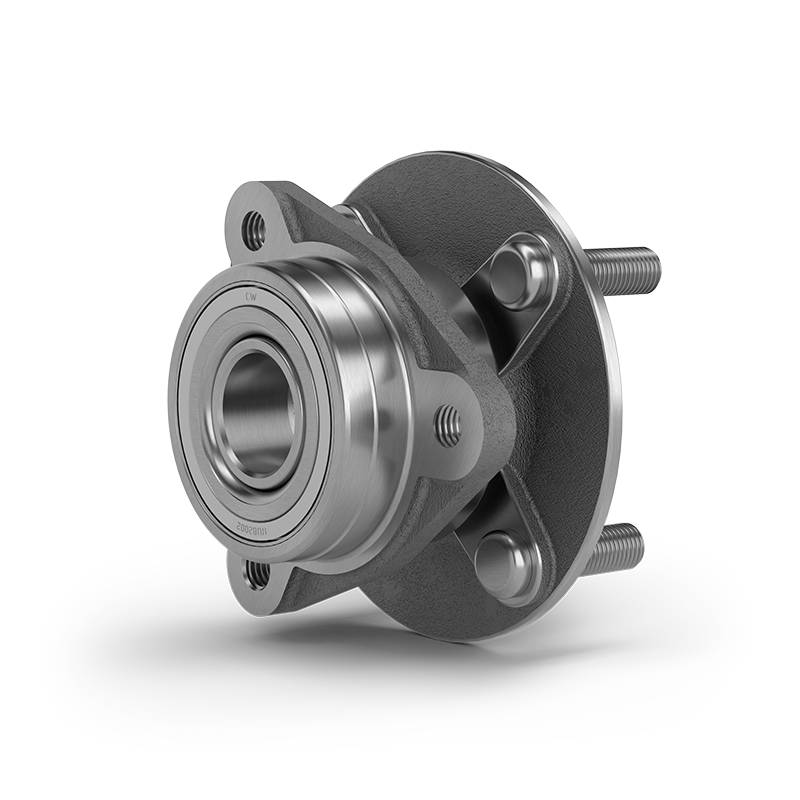

The corresponding load ratings must be maintained for the specified mileage of the wheel bearing. High stiffness of the wheel bearing is a basic requirement for you. You also want to generate as little CO2 as possible.

The perfect mix of sealing effect and energy efficiency for the bearing is important for this. After all, in wheel bearings, the seal causes by far the greatest amount of friction. However, for reliability and service life, the seal is also crucial. After all, you want to replace wheel bearings as late as possible. And if the time comes, installation should be simple and quick. What counts on the bottom line is the total cost of ownership for the end customer.

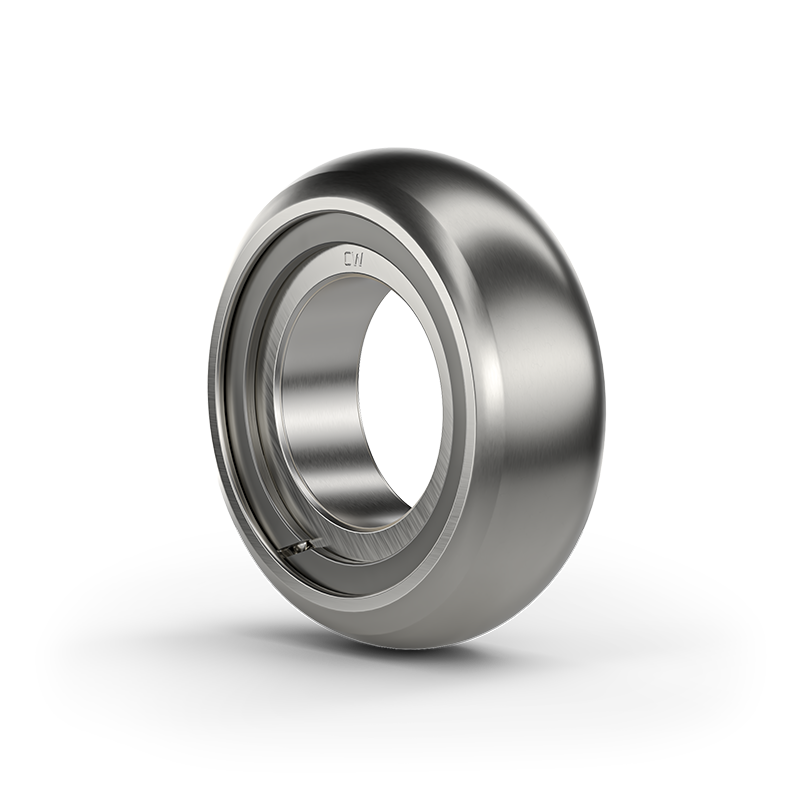

A solid needle roller bearing without a cage and with a crowned outer ring? We refer to this bearing briefly and succinctly as a roller. In drive shafts, it assumes the function of a joint. The largest possible number of needles ensures the maximum load carrying capacity of the compactly designed bearing. Naturally, we keep friction as low as possible in order to optimize power transmission. Vibrations and noise are not tolerated.

For smaller, more cost-efficient units with less space, we offer a reduced solution. This consists of only one outer ring and one set of needles. If you need further components for sideshafts and longitudinal shafts, we are certainly the right contact.

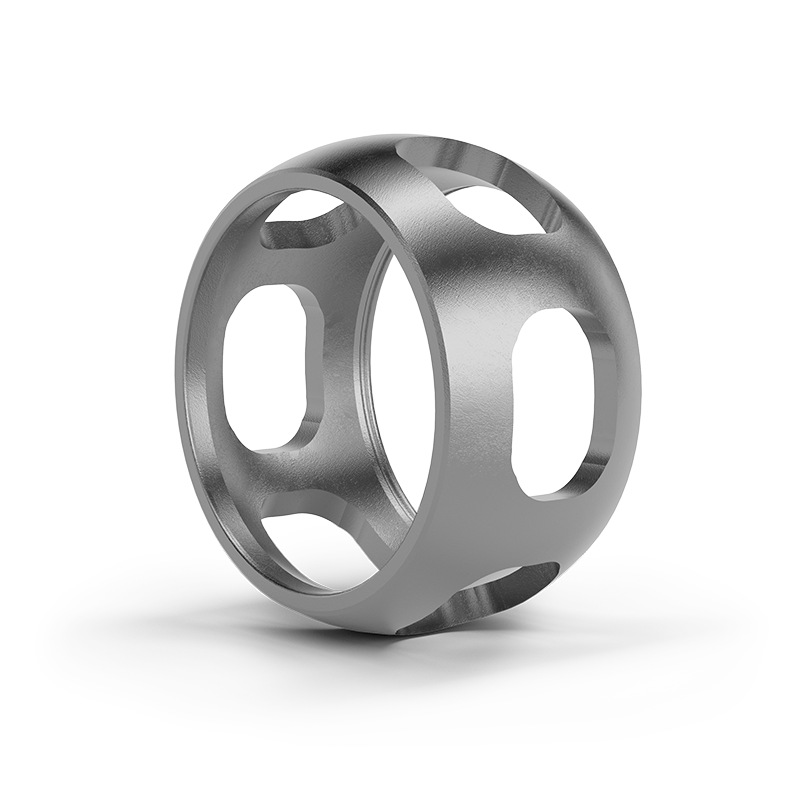

Constant velocity joints or CV joints (constant-velocity) are found in the sideshafts and longitudinal shafts of your driveline. What makes them special is that they allow a drive shaft to transmit power over a variable angle. In the process, neither friction nor backlash increase noticeably at constant speed. Depending on the type of drive and the mounting on the wheel or gear side, there are different requirements. We design the CVJ cage for your constant velocity joint to match the installation space.

As with our ball bearings, we trim the cages for energy efficiency and the quietest possible running. We will be happy to provide you with comprehensive advice on the development of your system.

If you wish, you can upload your technical specification or a drawing here.

Do you have specific questions about a rolling bearing in your application? Then please feel free to contact me directly.