Go Back

- Your solutions

- Products

- Services

- Industries

- Contact

Do you have questions about the configuration of your ball bearing? For example, which seal, grease or radial clearance is the best choice for your application?

The CW experts are there to help you in word and deed. By phone, digitally or in person at your site.

You need a real special solution? Your specifications are in good hands with us. For your customized solution, we calculate service life or frictional torque, for example, and adjust parameters such as external dimensions or internal geometry.

Our engineering team in Hamburg accompanies joint development projects from the initial idea to series production. Our site in Göppingen specializes in the application development of ball screws and worm shafts.

Do you have specific questions about ball screws or worm shafts in your application? Then please feel free to contact me directly.

With the help of CAD data, we create an approximate model - for example of your ball bearing. We then simulate the loads using defined boundary conditions. Through the FE simulation, we determine possible deformations or stresses.

The decisive question is: Will the component withstand the maximum loads? Based on the calculation results, we can derive a reliable forecast for this.

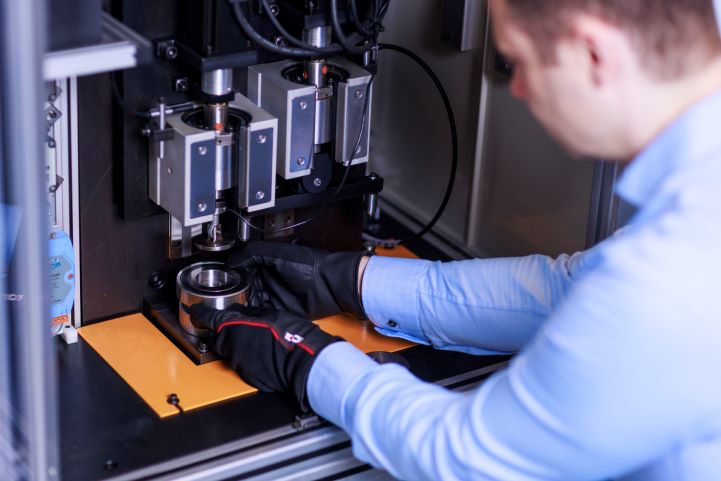

In order to test the prototypes of our development projects in detail, we have the most important test stands for your rolling bearing applications in Germany.

Worldwide, the portfolio of our test rigs includes a wide variety of testing options:

Do you have further test requirements? We look forward to your call. Discover our possibilities.

After a successful test, we examine your test specimens in our laboratory. The appropriate measuring equipment is available on site to record all important rolling bearing parameters:

On request, we can analyze your rolling bearings after they have been used in your application. As part of a possible failure analysis, we determine the exact reason why the bearings failed.

We will be pleased to provide you with everything you need to know about our products in your application as part of a technical training course:

We address important issues specific to your application:

On request, we will also be pleased to organize an in-house exhibition for your employees to answer their questions about our products.

Do you have specific questions about a rolling bearing in your application? Then please feel free to contact me directly.