Go Back

- Your Solutions

- Products

- Services

- Industries

- Contact

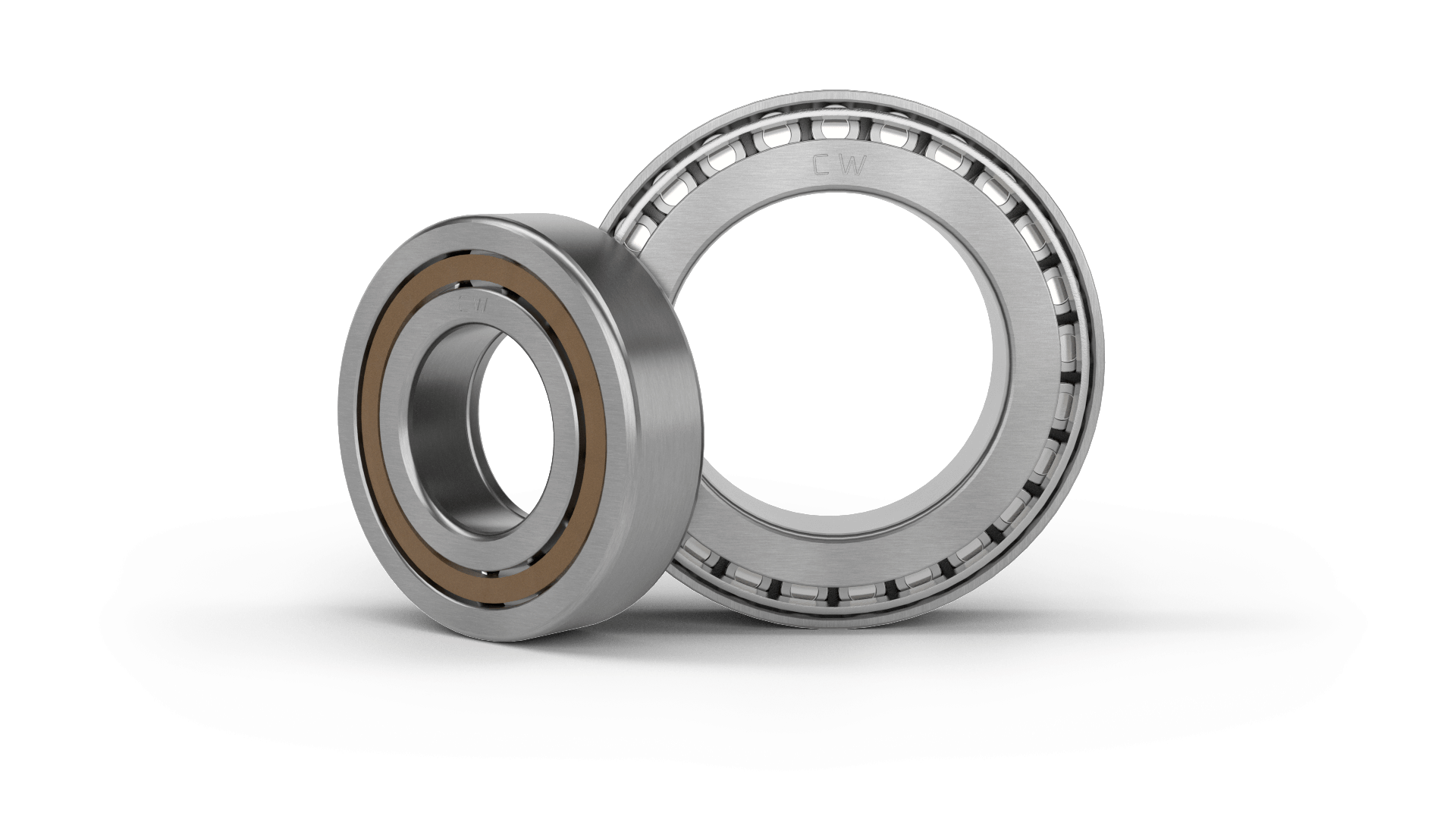

In applications where higher load ratings are required, roller bearings and their line contact are often the best solution. Therefore, we produce and supply suitable roller bearings for your applications. Of course, we match the most common tapered roller bearings or cylindrical roller bearings exactly to your requirements.

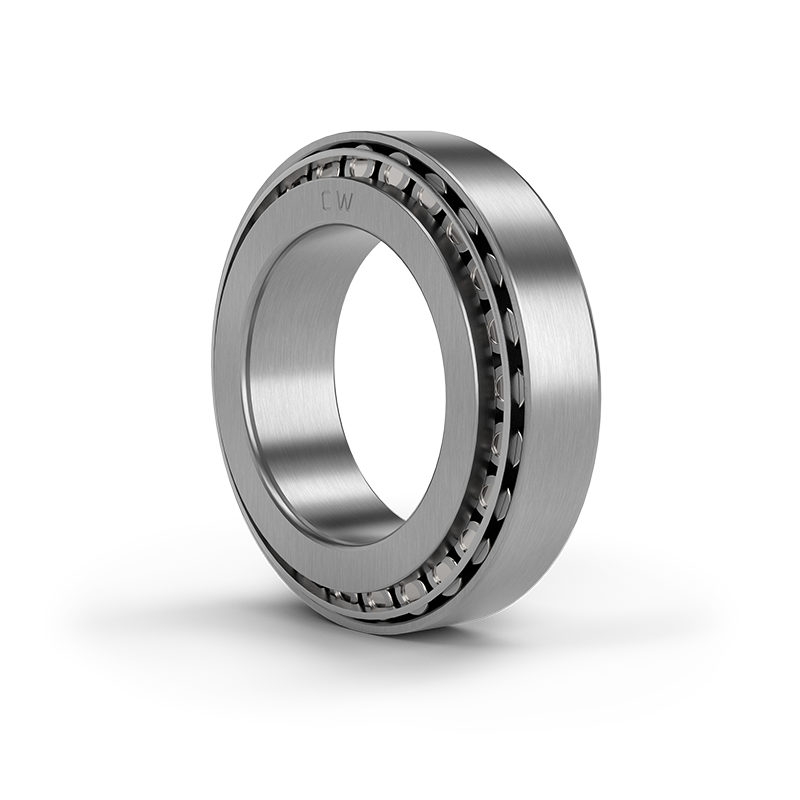

Does your bearing arrangement require being able to support very high radial and axial loads? Then we recommend our single row tapered roller bearings. Since tapered roller bearings are not self-retaining, the cup (outer ring) and the cone (inner ring, rollers, & cage) can be mounted separately for very easy assembly. Tapers are particularly suitable as locating bearings. Additionally, by application of a preload they can provide a rigid, clearance-free bearing arrangement.

Our portfolio includes series 302, 303, 313, 320, 322, 323, 329, 330, 331 and 332 - with metric and inch dimensions. On request, we will be very happy to build a custom solution for you.

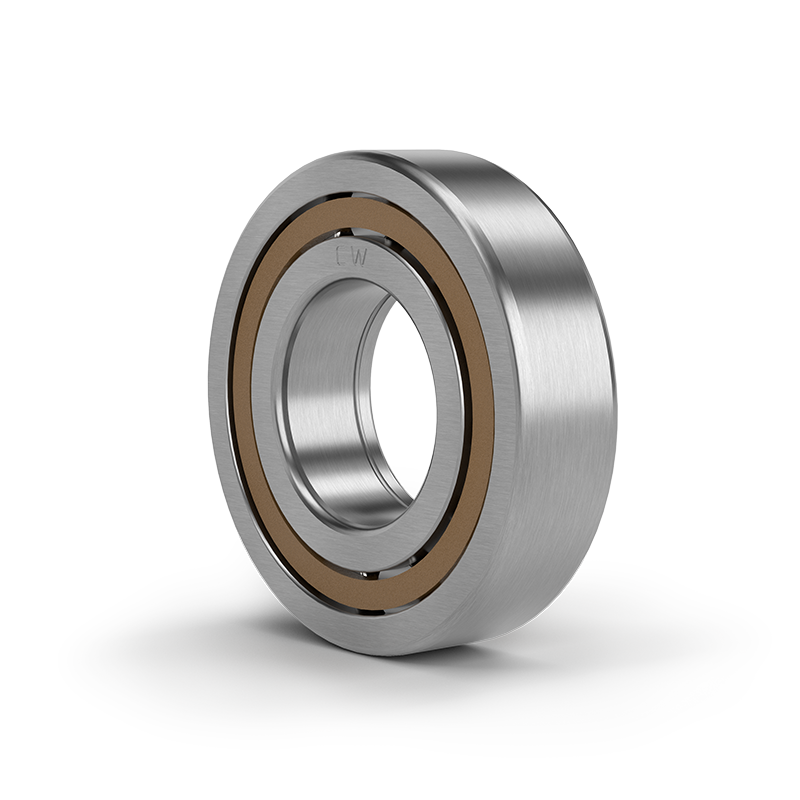

For particularly high radial loads, select our single row cylindrical roller bearings. As with tapered roller bearings, the inner ring and outer ring can be mounted separately. Do you need a locating bearing, a non-locating bearing or a support bearing?

With our designs NUP, N, NU, NJ, NH and NF, we have a suitable solution for each of your requirements. Depending on the design, our cylindrical roller bearings are also suitable for axial forces. For the cage material you have the choice between steel, plastic and brass. We will also be happy to supply a custom-made product as your solution.

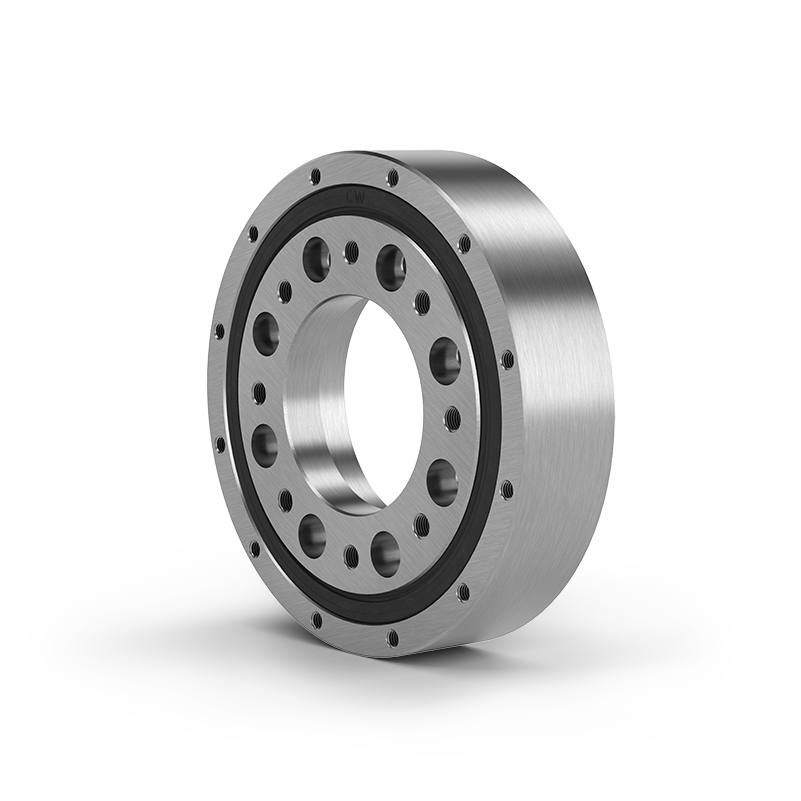

A crossed roller bearing is one in which the cylindrical rollers are arranged crosswise. These are guided by particularly low-friction spacers and run in a raceway ground at right angles. This makes the crossed roller bearing ideally suited for supporting axial and radial forces as well as tilting moments. Compared to two angular contact ball bearings, the crossed roller bearing fits within 50% of the installation space. Additionally, due to the line contact, the rigidity of the crossed roller bearing is more than 3 times greater. Of course, our crossed roller bearing also runs smoothly and uniformly under preload. Our tight manufacturing tolerances ensure this.

CW crossed roller bearings are suitable for applications with both rotating inner and outer rings. Depending on your requirements, we offer split or solid rings. The variant with solid inner and outer rings ensures maximum rigidity. Of course, we provide your crossed roller bearing with the lubricant of your choice and optionally with seals. As always, we can provide you with a completely customized solution on request.